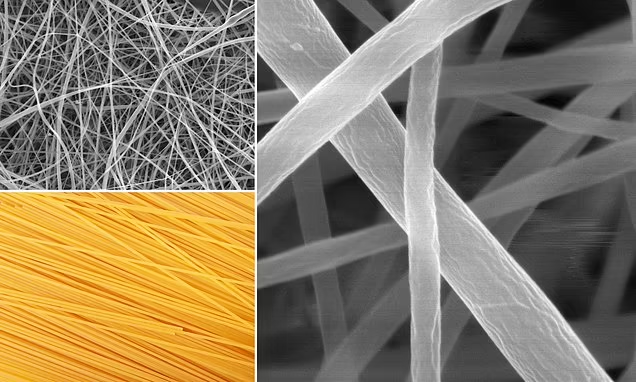

In a groundbreaking experiment, a team of chemists at University College London (UCL) has succeeded in creating the world’s thinnest spaghetti, a feat that is not only impressive but could also pave the way for significant advances in medical technology.

This innovative pasta is 200 times thinner than a human hair and is even narrower than some wavelengths of light, setting a new record in the realm of pasta-making. But while this ‘near-invisible’ spaghetti may not be a practical new dish for your dinner plate, its potential applications in medicine and other industries are what truly set it apart.

The Creation of the World’s Thinnest Spaghetti

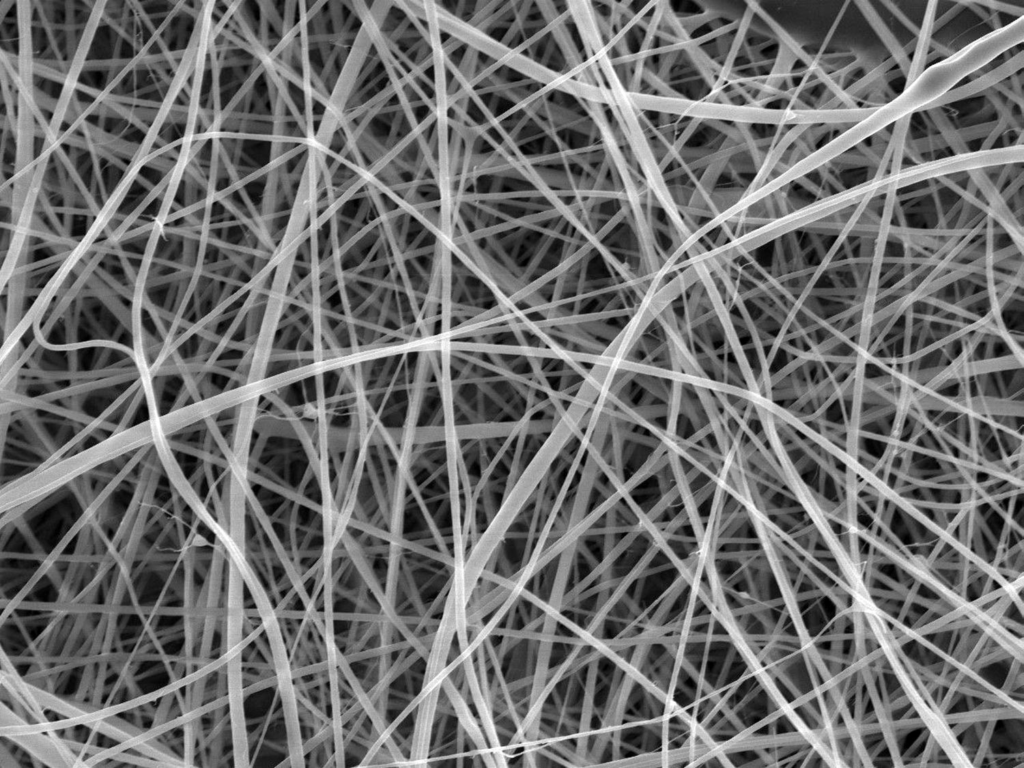

The team at UCL, led by Dr. Adam Clancy, used an advanced technique known as electrospinning to create nanofibers with diameters of just 372 nanometers—billionths of a meter. The result is a spaghetti so fine that it cannot be captured by any visible light camera or traditional microscope.

Instead, researchers had to rely on a scanning electron microscope (SEM) to capture the incredibly fine strands, scanning them with a focused beam of electrons. The deflection patterns of these electrons helped create an image of the tiny pasta fibers.

While pasta may traditionally be thought of as a food item, the purpose of this endeavor was not culinary. The creation of the world’s thinnest spaghetti is more about its potential for new scientific and medical applications.

Read : Amalfi Coast of Italy: Where Sea Meets Sky to Share Captivating Tales of Sunlit Shores

The research team employed a mixture of flour and formic acid, using the latter to break down starch into fine nanofibers. The result was a substance that is not only incredibly thin but also has unique properties that make it useful in various fields beyond food.

Read : AI Video of ‘Spaghetti Dance’ Goes Viral on Instagram: Watch Here

The scientists spent hours adjusting the flour mixture’s temperature to ensure that the spaghetti-like strands were created at the right consistency.

This process was crucial because, unlike traditional pasta-making methods, the electrospinning technique required careful manipulation of temperature and electrical charge to pull the mixture through small metal holes, producing fibers far thinner than anything produced in conventional pasta manufacturing.

Medical and Technological Potential of Nanofibers

While the creation of the world’s thinnest spaghetti might sound like a whimsical scientific achievement, its real potential lies in the material properties of the nanofibers it produces. Nanofibers are strands that are incredibly thin—often at a molecular level—and have a wide range of uses in medicine and technology.

One of the most exciting applications for these nanofibers is in the medical field. As noted by Dr. Gareth Williams, another key figure in the study, nanofibers, particularly those made from starch, show significant promise for use in wound dressings.

Their extremely porous structure allows for better absorption and fluid retention, which makes them ideal for use in bandages that can help heal wounds more efficiently. Additionally, the structure of nanofibers mimics that of the extracellular matrix—the network of proteins and molecules that surround and support cells.

This similarity makes them useful as scaffolds in tissue engineering, which could one day lead to the development of methods for regrowing damaged tissues or organs.

These nanofibers could also be used in the production of carbonized supercapacitor electrodes, which are essential for the development of energy storage devices.

Supercapacitors store energy more efficiently than traditional batteries, and the use of starch-based nanofibers could make this technology cheaper, greener, and more sustainable. With the global push for cleaner and more energy-efficient solutions, this is an area that holds great promise.

In addition to their medical applications, nanofibers are also being explored in environmental and industrial sectors. Their biodegradable nature makes them ideal candidates for use in a variety of sustainable technologies, from eco-friendly packaging to agricultural applications.

As industries worldwide seek alternatives to plastic and other non-biodegradable materials, the development of biodegradable nanofibers could be a key part of future solutions.

The Science Behind the Electrospinning Process

Electrospinning is the key technique behind the creation of the world’s thinnest spaghetti. This method involves applying a high-voltage electric field to a liquid mixture, causing it to form into ultra-fine fibers.

These fibers are collected on a surface, creating a mat of nanofibers. In the case of UCL’s pasta experiment, the team used a mixture of flour and formic acid, with the acid playing an essential role in breaking down the starch into finer strands.

The electrospinning process is extremely versatile, allowing for the production of nanofibers from a wide range of materials, including polymers, proteins, and starch.

This versatility makes it a powerful tool for creating nanofibers with specific properties that can be tailored for different applications. The technique is already used in various industries, from textiles to electronics, but the UCL team’s use of it to create edible, yet functional, spaghetti is a novel application.

The process begins with a liquid mixture—typically a polymer dissolved in a solvent—that is fed into a spinneret. The spinneret is connected to a high-voltage electric field, which causes the liquid to form a fine jet. As the jet moves through the electric field, the solvent evaporates, and the fibers solidify, forming a mat of nanofibers.

The resulting fibers are then collected and processed, depending on the intended use. In the case of the spaghetti, the goal was to create strands with a specific diameter, one that would allow them to be used in medical and technological applications.

In essence, the UCL team has created a material that is not only thinner than human hair but also possesses remarkable properties that could benefit a wide range of industries. Whether it’s in the field of wound care, energy storage, or sustainable materials, the potential applications for these nanofibers are vast and varied.

The creation of the world’s thinnest spaghetti by UCL chemists represents more than just a technological milestone; it showcases the innovative ways in which scientific techniques are being used to solve real-world problems.

While this pasta is unlikely to appear on restaurant menus anytime soon due to its tendency to overcook in less than a second, the breakthrough achieved by the UCL team has profound implications for a variety of industries.

From wound dressings to biodegradable materials and energy storage devices, the nanofibers created through electrospinning could play a critical role in shaping the future of medicine, technology, and environmental sustainability.

As researchers continue to explore the potential uses of these nanofibers, it is clear that the thinnest spaghetti ever created has opened up a world of possibilities for advancing science and improving lives.